Reduce setup time and minimize deviation risks

Keep – Complete control with digital setup cards

Keep is a cloud-based solution that gives you a complete overview of CNC programs, tooling, fixtures, and past production experience – all in one place, always accessible and up to date.

In day-to-day operations, valuable experience is often lost. With Keep, you make sure knowledge from previous jobs is preserved and reused. Simple, secure, and fully searchable.

Preserve your company’s know-how

Designed by operators, for operators

At Ignos, we develop our products in close collaboration with our customers, giving you the opportunity to influence both development and future features.

Keep is designed to be accessible, visual, and easy to use, for both operators and managers.

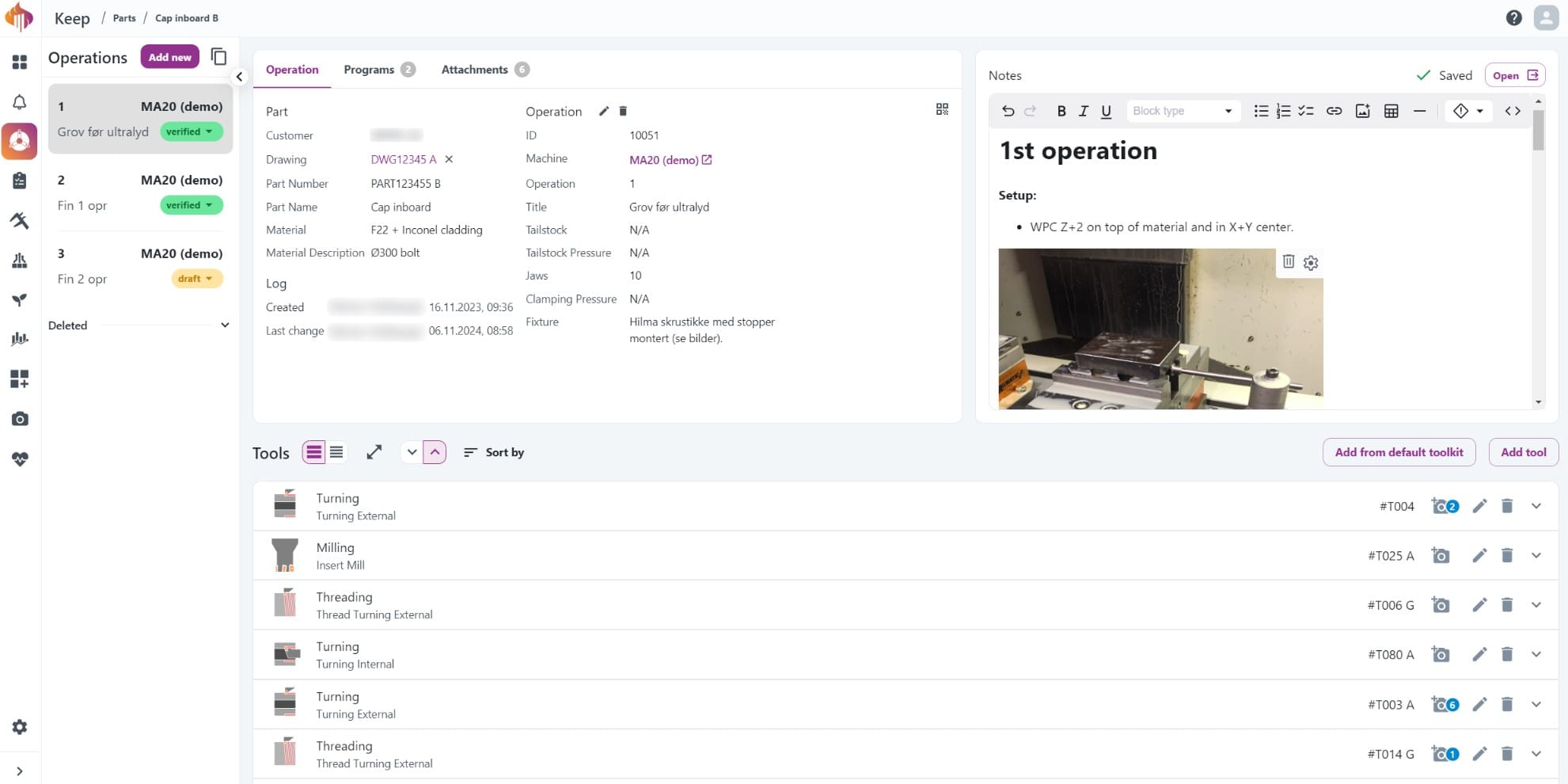

CNC program archive

A searchable database providing a complete overview of all CNC programs and operations.

Tool lists

Create detailed tool lists to ensure short setup times for future production runs.

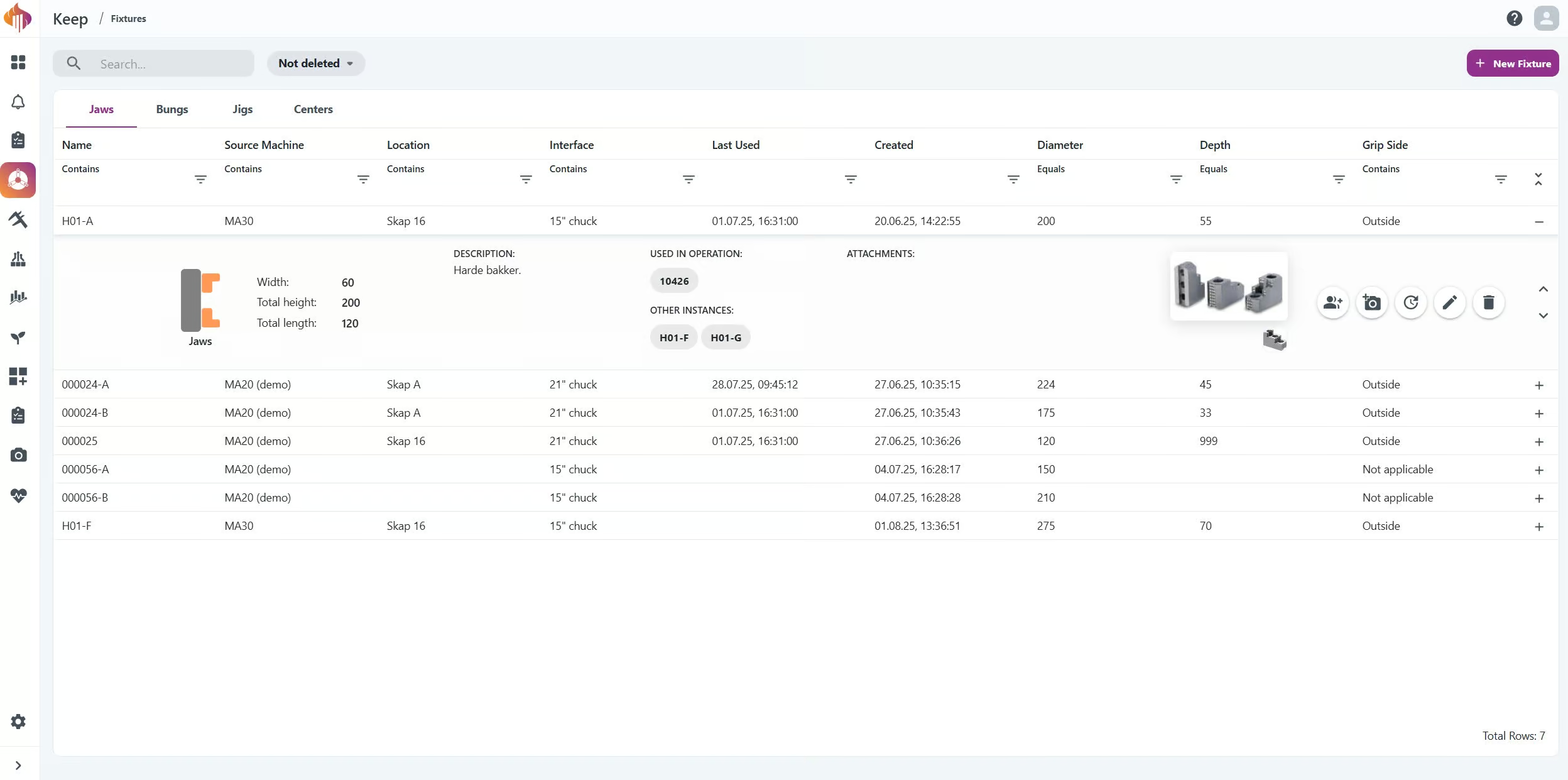

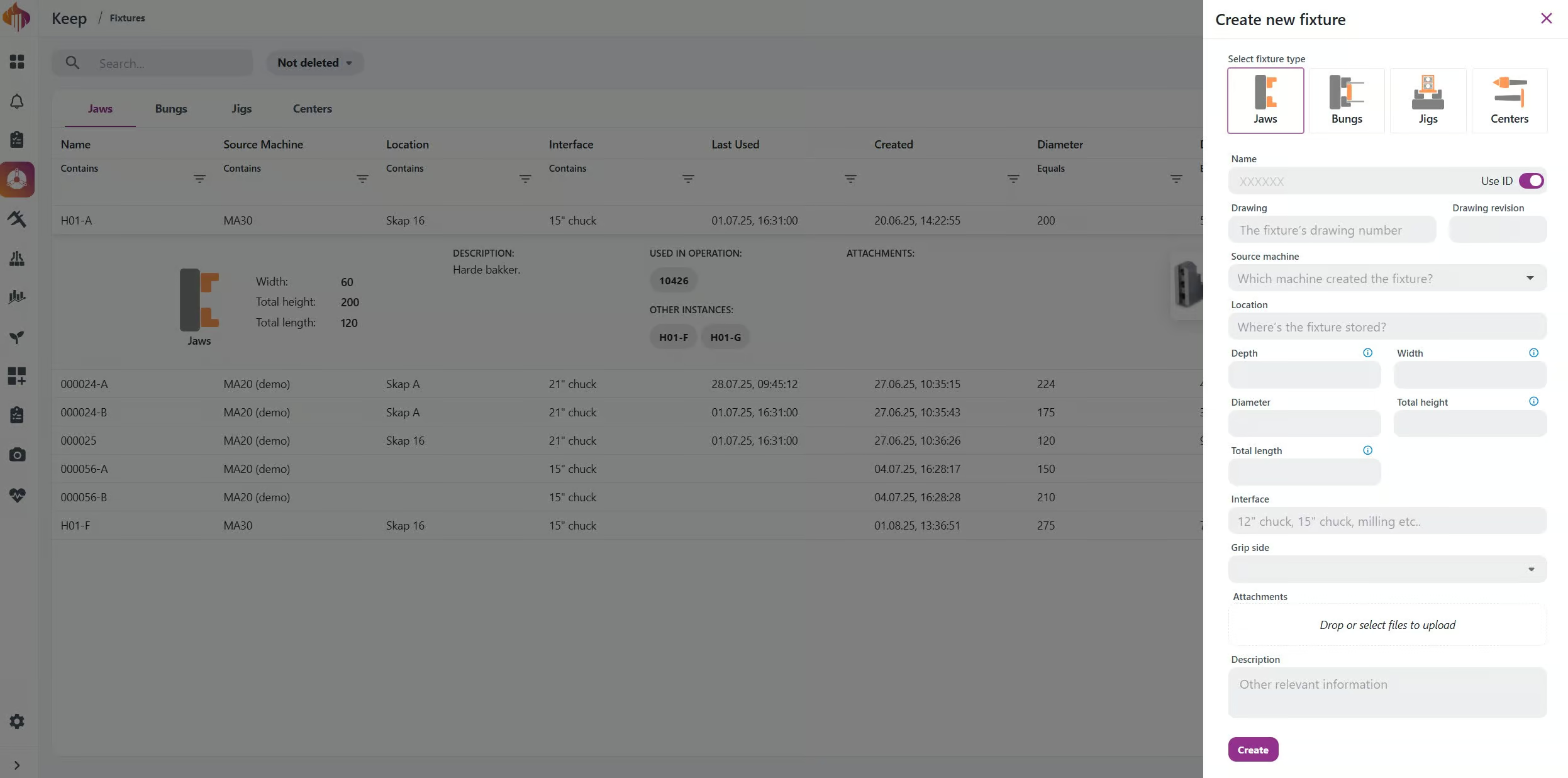

Dedicated fixture database

The Fixture module lets you easily see where each piece of equipment is located, who used it last, and what it’s used for.

Program transfer

Keep supports program transferring for all types of CNC machines.

Data security

All data is stored securely using modern security standards and encryption, ensuring safe handling of sensitive manufacturing data.

File and image uploads

Upload files and images in any format and link them directly to the relevant operation, tool, or fixture in Keep.

Seamless mobile and tablet use

Keep works seamlessly on mobile and tablet devices.

History

A complete record of all previously machined parts and processes, searchable by date, time period, specific resources, users, and more.

FAQ

Any questions?

Who is Keep for?

Keep is designed for machining companies and operators who want to:

- Reduce setup time by reusing previous setups and programs.

- Ensure consistent process execution across machines and operators

- Maintain full version control and backups of CNC programs

- Reduce the risk of deviations with verified operations

- Preserve experience and build a living knowledge base over time

What sets Keep apart from other solutions?

Keep is developed with the operator at the center and is suitable for both small and large machining companies. The system is intuitive and ready to use from day one – without complex IT-projects.

- Requires minimal training.

- Tailored to be useful for both offline programming and at-machine programming.

- Can be used with or without machine connectivity.

- Consolidates programs, tools, fixtures, and history in one place.

- Works seamlessly on tablets and mobile devices.

How does Keep support continuous improvement?

By preserving every detail from previous jobs, Keep makes it easier to:

- Reuse optimized setups.

- Share knowledge across teams and shifts.

- Track improvements over time.

- Systematically reduce sources of error and setup time.

You get a living knowledge base, not just static storage.

What can I document in Keep?

Keep lets you document and search for:

- CNC programs and revision history.

- Tool setups and cutting data.

- Fixtures, jaws, chucks, jigs, clamping pressure, and more.

- Operations, machines, and part information.

- Images, PDFs, and documents linked to parts, operations, tools, or fixtures.

- Comments, experiences, and improvement suggestions.

Everything is searchable by machine, part, customer, material, and more.

How do we get started?

To get started, you’ll need a Microsoft Entra environment (Azure AD) for authentication and access control. If you want to use the program transfer feature, you’ll also need a server.

Users sign in with their Microsoft accounts, and you manage access through your existing roles and security settings. Your data is handled in accordance with Microsoft’s security and privacy standards.

We support you through the entire process, from initial setup to everyday use.

Is Keep secure?

Yes. Keep uses:

- Modern security protocols and encryption.

- Microsoft Entra ID (Azure AD) for login and access control.

- Secure cloud storage, with the option for a local backup solution if needed.

You always have control over who has access to what, and you own your own data.

Does Keep require machine connectivity?

No. Keep can be used entirely without connecting to a machine. You still get:

- Full overview of programs and tools.

- Documented history and experience.

- A user-friendly interface for both mobile and desktop.

Direct program transfer is available where the machine supports it, but it’s optional.

How much does Keep cost?

Keep has a simple pricing model:

- Fixed monthly price per machine resource.

- Unlimited number of users.

- No hidden costs.

Contact us for a tailored offer for your company.